C4 DRIVELINE REINFORCEMENT

PLATES (P/N: ZPC4DRP).

For all 1984 - 1996 (C4)

Corvettes.

ZR51 PERFORMANCE (ZP) HAS DEVELOPED A BOLT-ON DEVICE THAT REINFORCES THE CONNECTING POINTS OF THE DRIVELINE SUPPORT MEMBER TO THE TRANSMISSION AND TO THE DIFFERENTIAL HOUSINGS.

WITH THE PLATES INSTALLED, FULL THROTTLE SHIFTING RESULTS IN THE VEHICLE JUMPING STRAIGHT FOWARD INSTEAD OF THE ASS END KICKING OUT TO THE RIGHT.

THE RESULTS IS ALMOST AMAZING AS AGRESSIVE

COST: Retail Price: $150 (Lifetime Warrantee on parts and workmanship)

Installation Time: 1hour (when performed as a stand-alone task)

Cryogenic Processing: add $15

Ask about member

discounts.

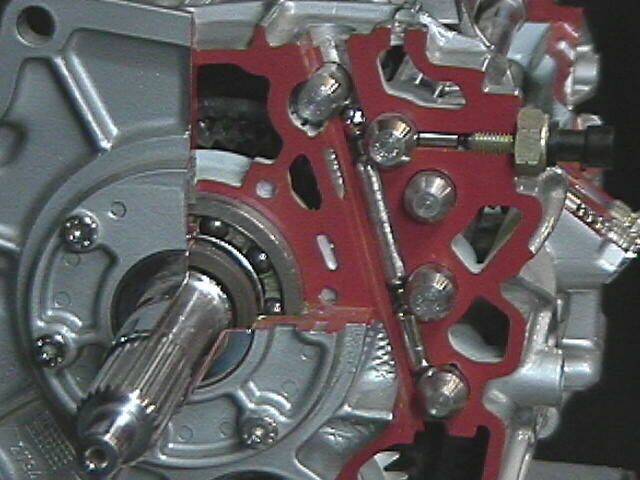

CONSTRUCTION:

This bolt-on device consists of 2 sets of 2"x3" reinforced all-stainless plates which are substituted for the original washers of the 4 beam fastening bolts. These plates sandwich the C-beam and clamp down the fastening surfaces with such a high reserve range of deflection resistance compared to the aluminum beam, that even the most violent shift will not induce deflection between the members. The bi-product of "driveline deflection" is best described as the car throwing one shoulder back when shifting hard followed

by slight to severe rear-end-kick-out to the right tendency.

Torque specs remain the same (front: 37ft.lb, rear: 59 ft/lbs).

GIVE YOUR C4 CORVETTE THE UPPER EDGE IN ACCELLERATION HANDLEING BY MAXIMIZING THE EFFICIENCY OF YOUR DRIVELINE PERFORMANCE.

Bill Boudreau bill777@inficad.com

ZR51

Performance www.zfdoc.com

(602) 740-6277

5612 East Almeda

Court,

Cave Creek, AZ

85331

-------

Good news! ZR51 Performance (Bill Boudreau) developed a set of torque/fixing plates that reinforce the mount points of the C4 Corvette driveline support beam. These plates "sandwich" the fastening points of the transmission and differential casing with 2" X 3" stainless steel reinforced plates. Most of the lateral deflection is removed from all modes of acceleration.

Especially the tendency for the car to throw its shoulder back during heavy acceleration up shifts. It's just like putting some C5 into your C4.

During torsional loading of the driveline, counter forces are imposed to the driveline that make it bend or flex (where allowed) from its original shape. The effect is commonly known as Driveline Lateral Deflection.

The C5's cleaner ride:

One of the best C5 Corvette features is the fully enclosed driveline support member.

By having the driveline tube connected to both clutch and trans housings, tortional-loading-induced deflection of the driveline does not have any place to "so-call" leak from the system. This clean method of transferring energy channels all forces to the drive train to the intended chassis mount points.

This is one of the reasons why the C5 gives a cleaner feel during acceleration.

Putting 2 & 2 together:

In the C4, lateral-deflection-induced tweaking does occur to varying degrees at the driveline support fastening points. The way that I discovered the need for these fastening plates was because of all the units that came across my bench had some degree of aluminum migration at the extension housing mount surfaces.

An important note to remember is that the units which were installed with the urethane adhesive (liquid nails tan colored goop) showed fewer signs of contact surface aluminum migration along with signs of partial surface contact.

How and why these DSRPs can help any C4 Corvette:

By maximizing the driveline support-to-transmission/differential case fastening-point

contact-surface-areas, the inherent flex at these points is absolutely minimized. This Driveline Support Reinforcement Plates (DSRP) disallows lateral deflection to propagate at these points, maximizing the potential of the drivelines design.

In short they are very trick. I am astonished that this type of aftermarket apparatus wasn't developed Years ago!

Yes, I am patenting this idea.

Here's the kicker on the design... with these plates, you no longer need to use a wrench to hold the fastening nuts on top while tightening or loosening the driveline support beam bolts. That was the original idea that leads me to this discovery. It wasn't until I installed DSRPs and drove the vehicle when I found this out. Eureka!

I've been testing these Driveline Support Reinforcement Plates (DSRP) for about 4 weeks now and I still notice the difference every time that I go for a drive :-).

These things are the ticket for cleaning up lateral deflection in C4 Corvettes. The car seems to remain straight as an arrow especially during high RPM aggressive shifts.

INSTALL INSTRUCTIONS

ZP Driveline Support Reinforcement Plates - P/N 1052DSRP

Installation:

1) Raise vehicle and suitably support.

2) Remove partial or complete exhaust system if necessary to achieve clearance for removal driveline support fasteners.

3) Support transmission and ready a secondary support device at differential.

NOTE: Removal and installation of the driveline support fastening bolts normally requires manipulating of the transmission and differential mount points. A screw lift or second jack is recommended.

4) Remove support beam fasteners, placing nuts and washers aside.

5) Clean the upper and lower surface area where the deflection plates will be seated.

6) Insert bolts through lower deflection plates noting the "SPEEDO" markings.

NOTE: The plate marked "SPEEDO" must be positioned has a trimmed corner for clearance of the speed sensor bulkhead of the extension housing.

7) Insert bolt/plate assembly through the holes and hand start the threads by 1 turn into the top deflection plate.

8) ALIGN DRIVELINE COMPONENTS: To ensure proper alignment of the driveline, a clearance of 45 mm +/- 6mm (1.77 in. +/- 0.236 in.) must be maintained between the top of the support to the underbody and a clearance of 28 mm+/-6 mm (1.1 in. +/- 0.236 in.) from the right side (passenger side of vehicle) of the support to the side wall.

9) Take these measurements directly above and to the right of the propeller shaft front yolk.

10) Tighten support bolts at carrier to 80 Nm (59 lb. ft.)

11) Tighten support bolts at transmission to 50 Nm (37 lb. ft.).

12) Remove transmission support(s).

13) Install exhaust (if removed).

14) Lower vehicle

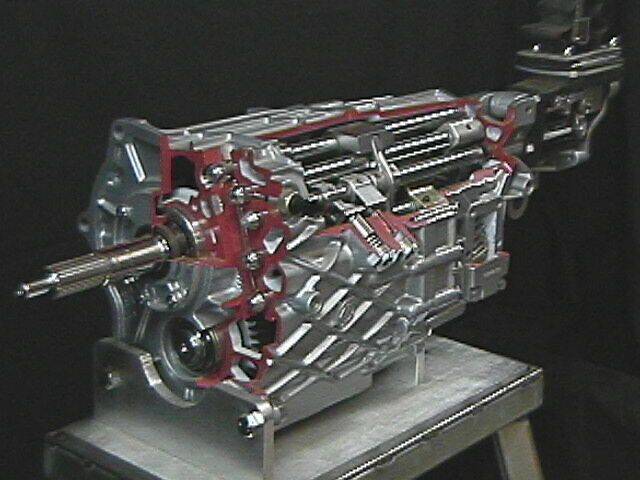

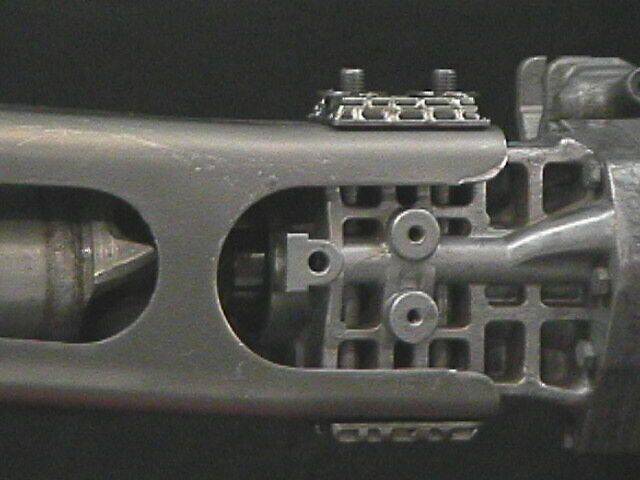

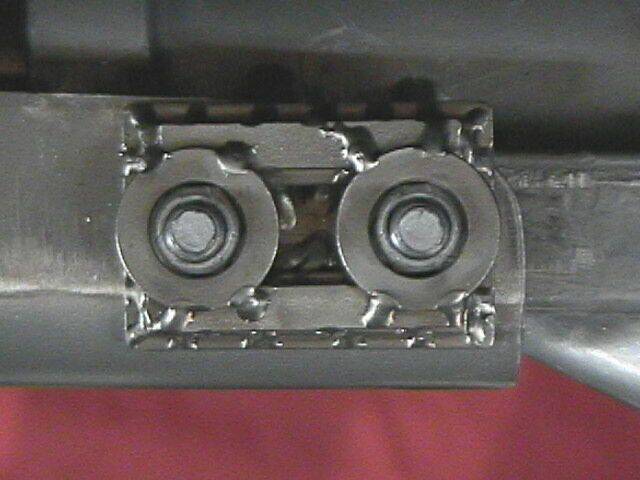

Below are cutaways of ZF six speed transmission